Sunrise Dam Gold Mine, by Calistemon on Wikipedia, CC 4.0.

The desirability of gold has made it a symbol of luxury, power, style and wealth but its rarity makes its extraction a tedious process. While gold can be found in loose sediments, the largest proportion produced worldwide is through hard rock mining.

Let’s delve into the process of developing a gold mine. From the beginning of the search for rich minerals to extraction to decommission of a mine. The process is a highly specialized process.

Exploration

Mineral exploration can be a long and complex process and exploring for gold is no exception. It begins with prospecting an identified region to determine if the mineral exists. Areas that have been mined before are always worth exploring.

The zone with potential is identified through structural mapping and geochemical sampling (soil is sampled using different assays to determine the amount of gold present). Experts in geology, engineering, geography and chemistry are heavily involved during this process. Depending on the jurisdiction, a license plus other additional requirements may be needed for gold exploration to commence.

When positive results are found, more in-depth investigations are carried out through drilling the potential ore body to different depths and analyzing collected samples. This is done through three resource level classifications:

The final analysis can include a combination of all three classifications. The area with the measured resource becomes the primary deposit to be mined while the inferred resource in the vicinity provides the possibility of future expansion.

This final assessment determines whether the gold resource has the economic viability to be extracted. If viability is established, the mining cycle proceeds. It’s important to note that exploration may go on through the mining cycle to extend the life of the mine. This process may also be repeated when returning to a known resource that was previously mined.

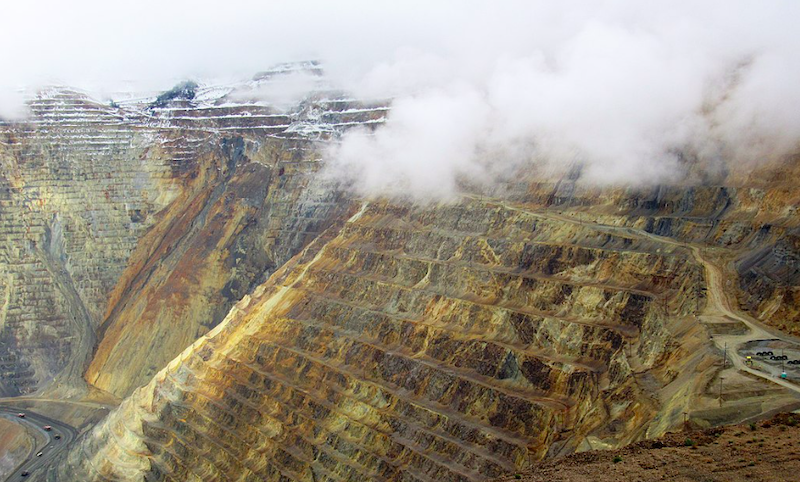

Bingham Canyon Mine, by Farragutful on Wikipedia, CC 4.0.

Preliminary Development of the Gold Mine

After positive results are found in the area of interest, the mining entity should lay a claim to the discovery and obtain appropriate licenses and permits for the planning and construction phase to start in earnest. The permits and licenses outline statutory obligations, environmental and land management guidelines as well as other requirements.

The necessary infrastructure such as workers’ housing, roads, railways, bridges and other amenities are constructed to support the gold mine’s operational and logistical processes. The scope of development depends on the size of the resource and the processing capacity needed. After building the physical infrastructure, production activities such as excavation, drilling and blasting can be initiated.

Operating The Gold Mine

The physical extraction of the gold ore may be done by open-pit mining if the deposits are found relatively close to the surface or underground mining if the deposits are located deeper into the ground. Open-pit mining is the most common method for large scale operations due to its low capital and operating costs, ease of extraction and leeway to selectively mine specific grades of gold ore.

An open-pit (also known as open-cast) gold mine is developed by removing the top soil and rock from the site and digging a large pit with wide steps known as benches. The stepped sides are angled to prevent avalanches. A haul road is built on the side of the pit, allowing trucks to carry material to and from the mining site. The waste material is transported to a waste dump which can also be stabilized by tiers and steps. The waste can be used for future reclamation of the site.

Heavy machinery is used to dig up the ore or where hard rock is prevalent, drilling or blasting is used to break it up. Excavators are used to dig up the gold ore which is then transported to the processing plant.

The exploration results will normally indicate the different grades of gold ore for the entire site. This information is helpful when determining which part of the mine is viable for gold extraction. When global gold prices are low, it is desirable to focus on extracting higher-grade ores to remain profitable. When prices rise, the low-grade ores can be extracted to offset the increased cost of production arising from processing higher volumes of ore.

The mine’s operations should be continuously evaluated to reflect market dynamics and ensure profitability throughout its life cycle. New technology can be deployed to improve efficiencies and safety for workers.

Aerial photo of open pit mine in Ural Mountains, Russia.

Gold Processing

The most common and cost-effective way to process the extracted ore into gold is through the heap leaching process (cyanide extraction method). This process has low production costs, can be deployed quickly and is easy to scale up.

The raw ore is placed into the primary crusher and ground into fine particles. During this process water is pumped into the mill to turn the crushed ore into slurry.

The slurry is fed into tanks filled with sodium cyanide which leaches the gold from the rocks. As the process continues, activated carbon (coconut husks) is pumped upstream to capture the leached liquid gold.

The captured gold is washed out of the activated carbon using a gold desorption column.

The resulting mixture is melted in a furnace causing the gold to sink to the bottom leaving the remaining waste to float. The waste is poured out, leaving behind the gold.

The waste (processed ore) known as ‘tailings,’ is pumped into a settling for further treatment and disposal.

Decommissioning

The end of a gold mine’s life begins when the remaining ore body becomes unprofitable to mine or the deposit is depleted. The end of a mining cycle is anticipated early in the mine design process and becomes an integral part of it. This makes it easier to minimize environmental damage and plan how the land will be utilized in future. After the mine has been dismantled, the rehabilitation process begins.

Rehabilitation

To limit the environmental damage of a gold mine, good management of waste dumps and rehabilitation of the mining site are critical. The waste material from the mining operation can be used to fill up the open pit. If the pit cannot be filled up, the area must be fenced off to prevent access and avoid accidents. Some decommissioned open pits have been allowed to fill up with water and used as lakes for recreational activities.

The mine tailings can also be stabilized by simply flattening the dump and if the ore contains sulfides, it is covered with a layer of clay to prevent acid mine drainage.

Fresh soil can then be used to cover the area before new vegetation is planted. The preference for topsoil as well as subsoil is oxidized schist (brown rock). This is a metamorphic rock in grain form that contains several plant nutrients including nitrogen, which are effective in revegetation.

A gold mine’s land reclamation process can be tedious and time-consuming. Regulators regularly monitor the progress to ensure conformity with license conditions. The process of reclaiming a gold mine can be costly and may take years to complete. However, the environmental safeguards are meant to protect habitats and return them to normalcy after the mining operation has closed.

Conclusion

The construction and operation of a gold mine requires a huge capital investment. Depending on the regulations, size of the development, complexity of construction and the location, the process of setting up the mine could take years before any gold ore is milled.

Areas that have been mined before are always preferred for exploration. Some sites can be explored, mined, processed and rehabilitated multiple times as new technologies reveal the existence of more gold deposits.

How Cyanide is Used to Extract Gold from Rock

The Homestake Mine – South Dakota’s Largest Gold Deposit